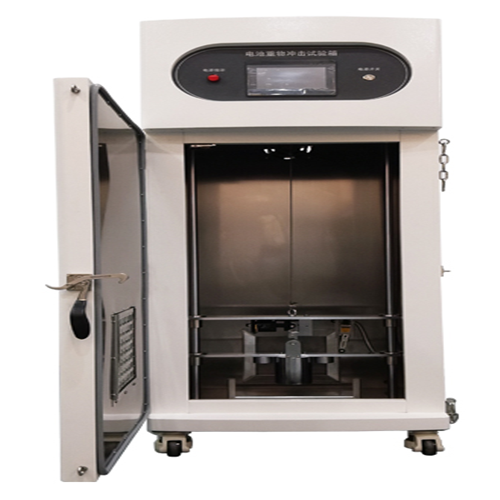

Battery impact tester

Product introduction

The test sample cell is placed on a flat surface with a 15.8±0.2mm(5/8 in)

diameter rod placed in a cross position over the center of the sample. A 9.1kg or

10kg weight is dropped from a certain height (610mm or 1000mm) onto the

sample. cylinder

When the battery is subjected to impact test, its vertical axis should be parallel

to the plane and perpendicular to the vertical axis of the steel column. The most

axis of the square battery is perpendicular to the steel column, and the largest surface

is perpendicular to the impact direction. Each battery receives only one impact test.

The battery does not catch fire or explode.

Meet the standard

GBIT31485-2015 "Safety requirements and test methods of power Batteries for

Electric Vehicles"

GB/T31241-2022 "Safety requirements for lithium-ion batteries and battery packs

for portable electronic products.

UN383 United Nations Manual of Tests and Standards for the Transport of

Dangerous Goods

IEC62133 "Safety requirements for batteries (groups) composed of cells and for

use in portable equipment"

UL1642-2012 "Inner Battery Standard"

Main parameter

Inner box size :550x550x1440mm(W x D x H)

Equipment dimensions :660x900x1720mm(W x D x H)

Material :SUS201 stainless steel plate, thickness 1.2mm and coated with Teflon

Outer box material: 1.5mm thick cold rolled steel plate paint treatment

Observation window: 250x250mm tempered glass, transparent window with

stainless steel mesh.

Lighting device: The machine is equipped with a light inside to facilitate the

observation of the state of the tested sample.

Smoke outlet: 100mm in diameter, located at the rear of the box.

Pressure relief port: The opening size is 200x200mm, located at the back of the

box. When the sample is exploded, the pressure relief port will pop open and remove

the pressure.

Door: single door open left, door equipped with safety limit switch, side equipped

with explosion-proof chain to ensure the safety of personnel.

Ball weight: 9.1kg, 10kg, 0.1kg

Impact height :0-1000mm, commonly used test height 610 —— 25mm

Control mode: touch screen control

Displacement accuracy: 5mm soil

Impact mode: lift the falling ball to a certain height and release it. The falling

ball falls freely in the vertical direction without tilting or shaking.

Metal rod: Diameter 15.8±0.2mm steel rod

Maximum battery size :200x200x200mm

Impact surface :45# steel paint treatment, thickness 15mm

Equipment weight :270kg

Power supply :AC220V

Power :600W

Leave Message Get Price