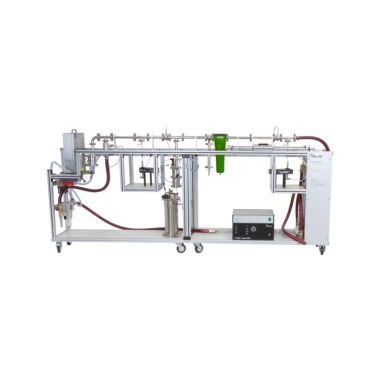

Gravel Impact Tester

The gravel impact tester is a professional testing equipment used to evaluate the ability of materials or components to resist gravel impact.

Working Principle

When the equipment is running, the gravel is first loaded into the funnel, and a high-speed airflow is generated through the airflow control device. The vacuum formed sucks the gravel into the gun assembly and sprays it onto the surface of the sample fixed on the fixture at a certain speed and angle. Simulate the scene of the vehicle body parts being hit by road gravel during driving, and evaluate the impact resistance of the material or component by observing the damage on the sample surface, such as whether there are dents, cracks, peeling, etc.

Application Field

Automotive Industry:

Widely used to test the stone impact resistance of automobile body panels, chassis, engine hoods, fenders, rearview mirrors and other components to ensure that the vehicle can resist gravel impact during driving, extend the service life of components, and improve the safety and durability of the vehicle.

Aerospace:

Impact resistance test of key components exposed to the outside such as aircraft skins and wing leading edges to ensure that the aircraft can withstand the impact of particles in the air during high-speed flight.

Rail transit:

used to test the ability of train body surface materials, window glass and other components to resist the impact of gravel and other foreign objects to ensure the safety of train operation.

Building materials:

Evaluate the performance of exterior wall coatings, decorative panels and other materials in outdoor environments to resist the impact of sand and gravel particles to ensure the integrity and durability of the building's appearance.

Leave Message Get Price